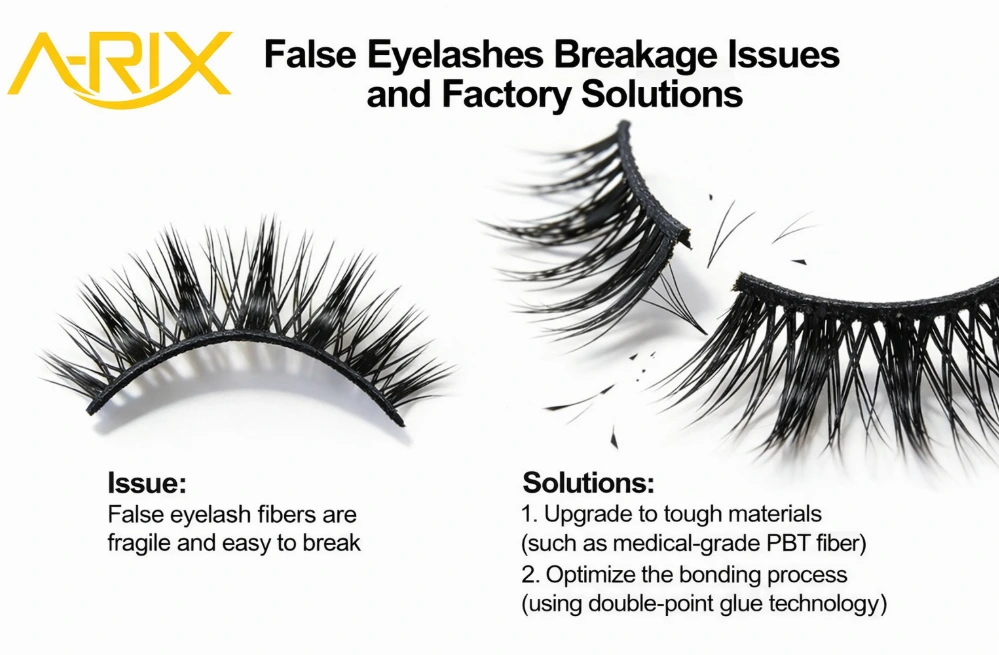

False eyelashes serve as a key element in beauty routines. They boost the eyes by providing extra volume, length, and flair. Yet, numerous users encounter a frequent annoyance. Lashes tend to snap, warp, or lose form after just a handful of applications. This problem not only harms the user’s satisfaction but also damages brand image and customer confidence. Grasping the main factors behind lash weakness, along with how expert producers like A-RIX tackle these issues, proves essential. It helps professionals and companies aim to offer reliable goods.

Common Reasons Why False Eyelashes Break Easily

Poor Material Quality Leads to Fragility

The selection of materials plays a direct role in the sturdiness of false eyelashes. Inferior synthetic fibers typically show little bendability and pulling power. As a result, they easily crack while putting them on or taking them off. These man-made fibers come from synthetic sources. Workers weave and sharpen them, which creates a pointed, clear end. Although they might display a shiny look, such fibers remain stiff and less tolerant to pressure.

Moreover, uneven thickness in the fibers leads to irregular strain when people bend or handle the lashes. Bands crafted from cheap plastic or glue-covered substances often grow frail after multiple uses. They also weaken from contact with makeup removers.

Manufacturing Defects Compromise Durability

Inconsistent production methods stand as another primary cause. If the adhesive does not cure properly during assembly, it creates fragile connections. Fibers may separate from the band at those spots. Mistakes in hand-cutting can produce uneven builds. This happens especially when layers fail to line up or space out correctly. Those stress areas turn into weak links during actual use.

Improper Packaging Causes Deformation

Even solid lashes can suffer if the packaging lacks proper design. Boxes without firmness permit squeezing during delivery. Trays that do not hold the lashes’ natural bend lead to twisting. These clear holders firmly place lashes to avoid warping, pressing, and dirt buildup. Contact with dampness or sunlight during keeping or moving speeds up wear on the materials.

How Lash Factories Address Quality Control Challenges

Use of Advanced Materials Enhances Longevity

Professional producers choose top-tier materials to fight snapping. PBT is a milky white translucent to opaque semi-crystalline thermoplastic polyester Due to its excellent styling stability, it is also called shape memory fiber. Lashes made from PBT keep their wave and form for a longer period than usual synthetic options.

The New Wet Spiky Look Half Eyelash Strip Lash shows this method clearly. It uses fibers from trusted names like DUPONT and TORAY. This choice guarantees better feel and bendiness.

Stronger cotton bands or see-through flexible bands also improve the base’s toughness. They help reduce separation and breaking.

Precision Manufacturing Minimizes Structural Weaknesses

New tech advancements hold a central spot in boosting lash strength. Machines for automatic positioning ensure steady gaps and fullness. This avoids fragile areas. Laser tools for cutting deliver smooth borders and even forms.

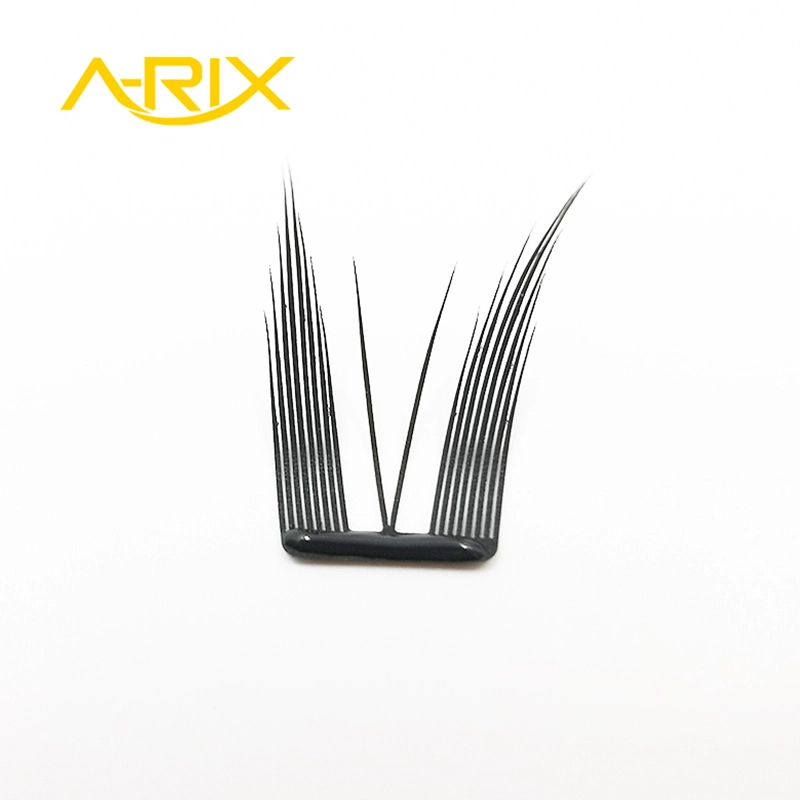

For example, the Pre-glued Lazy Cat False Eyelashes come from laser-cutting and hydraulic shaping processes. Every small group weighs just 0.002g. It has a 0.035mm very thin base. That base weighs 50% less than older cluster types. Thus, it brings top-level ease and lasting power.

Optimized Packaging Preserves Lash Structure

Producers put resources into containers that protect the build during travel and storage. Paper Card Box For Strip Eyelash Recycle Ecofriendly FSC Certificated and Paper Card Box For DIY Lindividual Cluster Eyelash Recycle Ecofriendly FSC Certificated serve as samples of green options. They blend safety with earth-friendly traits.

This kind of container features sturdy outside layers and tailored inner holders. Those holders support the lashes’ bend, so they reach users in ideal condition each time.

The Role of Adhesive in Lash Durability

Low-Adhesion Formulas Result in Lash Detachment

Glue plays a vital part in how well lashes perform. Feeble glue links cause early separation of lashes. This occurs particularly at the ends. If curing happens unevenly, the stickiness varies along the lash line. Certain parts then lift or break more readily under force.

Overuse of Adhesive Causes Band Stress

On the other hand, too much glue brings extra hardness. Over time, this can split the lash bands. Buildup from repeated glue use creates rigid spots. That rigidity hurts the band’s ability to flex, mainly in cotton-thread or plastic bases.

Pre-Applied Adhesive Enhances Application Stability

To fix this concern, ready-to-use glued options provide exact glue amounts from the factory. They secure strong links without reducing stretchiness. The Pre-glued Lazy Cat False Eyelashes illustrate this well. Their built-in glue systems allow wear for up to 7 days. No need for fresh glue. This beats standard glue-on lashes by a wide margin.

Impact of Design on Lash Breakage Resistance

Imbalanced Weight Distribution Strains the Band

Design influences strength too. Thick clusters at the outer edges can curl or bend during removal. This puts twisting force on one side of the band. Uneven spread of fullness focuses pressure in key zones. As a result, it leads to tears or folds.

Inflexible Designs Limit Reusability

Lashes that do not move well with eye blinks or face motions often crack at fixed points. Stiff styles might appear bold, but they usually give out fast. This happens if they fail to fit natural eye shapes.

Ergonomic Design Improves Wearability and Strength

Bands with a natural curve that match the eye line cut down on physical strain a great deal. The New Wet Spiky Look Half Eyelash Strip Lash employs a partial strip style. It directs pull to the outer areas. This lowers stress on the whole band. At the same time, it boosts the eye-catching effect.

Importance of Testing and Certification in Product Reliability

Lack of Standardized Testing Increases Failure Rates

Without uniform standards, durability can vary across batches even within the same brand. Consistent product performance requires rigorous quality testing under controlled conditions.

Environmental Testing Ensures Real-Life Performance Stability

Producers mimic everyday conditions like moist air and heat changes. They check how lashes endure during normal use. This builds trust that lashes will not weaken suddenly in actual situations.

Third-party Certifications Reinforce Quality Assurance Claims

Approvals like FSC for containers confirm following sector rules for green practices and container toughness.

How Sustainable Practices Contribute to Lash Integrity

Ecofriendly Materials Offer Both Strength and Responsibility

Containers like the Paper Card Box For Strip Eyelash Recycle Ecofriendly FSC Certificated prove that green choices pair well with product toughness. These clear holders firmly place lashes to stop twisting.

Reduced Chemical Load Preserves Material Properties

Skipping strong solvents in production keeps materials supple. It also cuts down on becoming brittle as time passes. This approach gains more attention in green false eyelash making.

Sustainable Design Encourages Reusability Without Damage

Builds that consider both lasting power and reuse let lashes serve multiple times. They hold their form and comfort. This matches what buyers want in thoughtful beauty items.

Factory Innovation as a Driver of Product Improvement

Integration of Technology Streamlines Quality Control

Modern tools like 3D printing and laser shaping reduce mistakes by people in forming lashes. Each item then fits tight measures for balance and power.

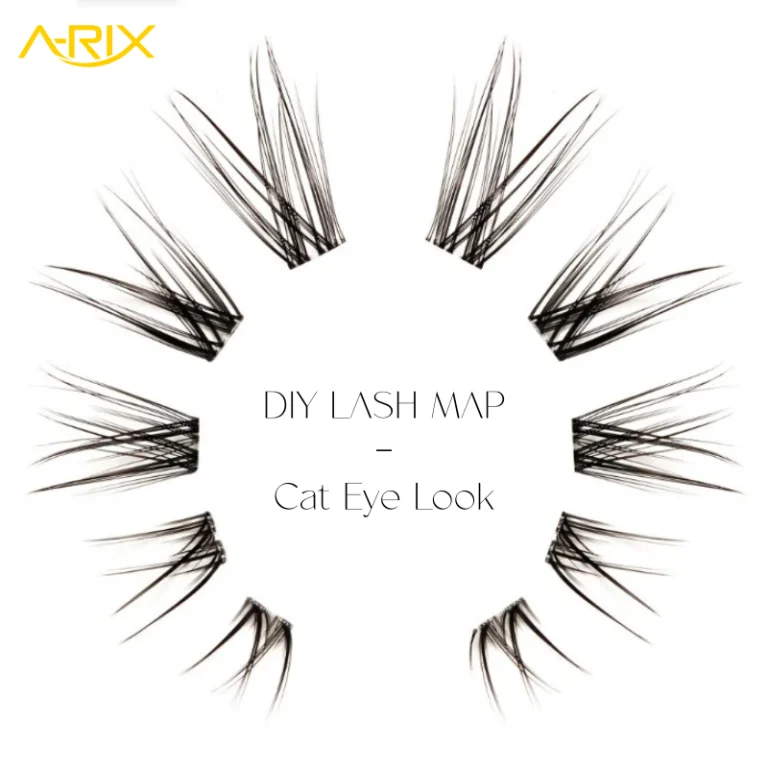

Customization Capabilities Meet Diverse Market Needs

Today’s plants handle various eye forms without hurting build strength. Custom services from A-RIX let companies shape goods to fit. They ensure lasting quality through smart building steps.

Continuous R&D Elevates Product Standards

Ongoing input from users and fresh ideas appear in their news updates. Through this, A-RIX keeps advancing lash styles and strength. It positions them as a dependable ally for companies wanting strong false eyelashes.

Check out more than 2,000 options in A-RIX’s catalog. See how their full production setup improves steady quality in large amounts. For custom help, their group awaits messages on the contact page.

FAQ

Q1: Why do my false eyelashes snap after just one use?

A: This usually stems from low-quality materials such as basic synthetic fibers or faulty glue use that weaken the overall build.

Q2: What makes PBT fiber better for false eyelashes?

A: PBT offers strong resistance to heat, toughness, fatigue resistance, and resistance to organic solvents, which suits it well for keeping waves and form over extended periods.

Q3: Are pre-glued lashes better than glue-on types?

A: Yes, pre-glued lashes like the Pre-glued Lazy Cat False Eyelashes deliver even stickiness and remove mistakes in putting them on.

Q4: How does packaging affect lash durability?

A: Bad packaging lets twisting happen in transit; firm FSC-certified boxes keep the original lash form and stop breaks.