A Behind-the-Scenes Look at OEM & Private Label Eyelash Manufacturing

When beauty brands decide to launch their own eyelash line, most of the real work does not happen in marketing meetings or on social media. It happens inside the factory. For B2B buyers sourcing from China or other manufacturing hubs, understanding how an eyelash factory actually produces a private label product helps reduce risk, avoid miscommunication, and build a more stable long-term partnership.

This article explains how a professional eyelash factory works with private label clients, from the first inquiry to finished goods ready for shipment. It is written for brand owners, distributors, and importers who want to understand the manufacturing process rather than rely on surface-level promises.

From Idea to Specification: Where Private Label Really Begins

Private label eyelash production usually starts long before any physical sample is made. A factory does not simply “copy” a lash style. Instead, it translates a brand’s idea into technical specifications that can be produced consistently at scale.

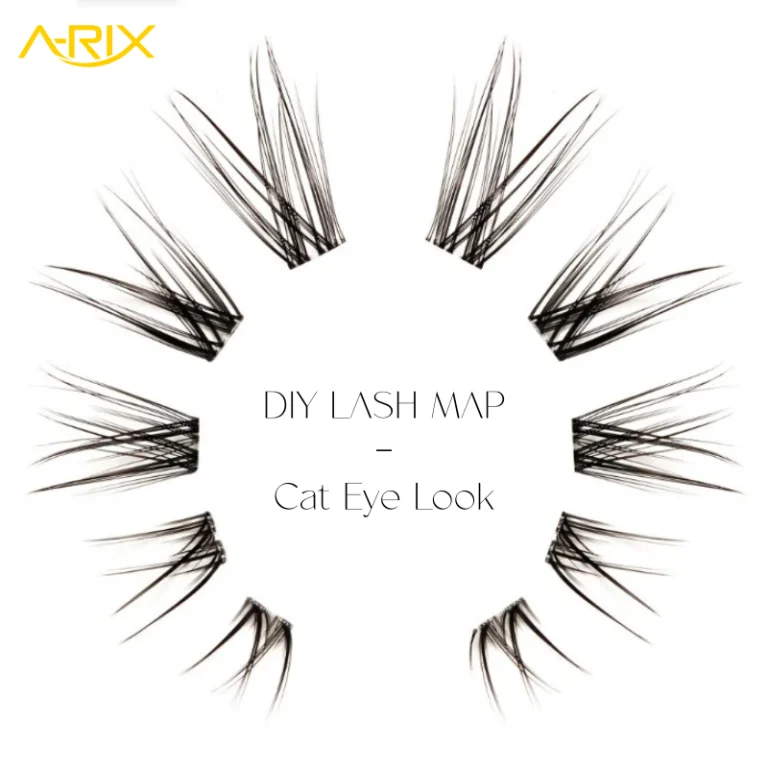

Most buyers come with reference images, competitor samples, or a general concept such as “natural volume lashes for the U.S. market” or “dramatic cluster lashes for online sales.” At this stage, the factory’s role is to clarify details that directly affect production: lash material, curl type, thickness, length range, lash density, and tray format. These details may seem minor, but they determine whether a product can be reproduced reliably across thousands of units.

Experienced factories will usually suggest adjustments based on market trends and production realities. For example, a design that looks good in a photo may not perform well during application, or may be too fragile for mass production. These early discussions shape the final product far more than most buyers realize.

Material Selection and Consistency Control

Once specifications are confirmed, material selection becomes the foundation of private label quality. For most modern eyelash products, PBT fiber is the standard, but not all PBT is the same. Factories source fibers with different softness, elasticity, and surface finish depending on the target market.

This is one of the areas where long-term SEO value matters for buyers: search terms like “eyelash material quality” or “private label lash consistency” often reflect real sourcing concerns. In practice, factories test fiber batches for curl retention, flexibility, and uniform diameter before moving into production. If material quality fluctuates, the final product will not match the approved sample, which leads to disputes and delayed orders.

For private label clients, consistent material sourcing is often more important than achieving the lowest unit price.

Lash Production: Where Craftsmanship Still Matters

Despite automation in many industries, eyelash manufacturing still relies heavily on skilled manual processes. Whether producing classic lash extensions, volume lashes, or DIY clusters, much of the shaping, alignment, and bonding is done by trained workers.

In a private label project, factories typically produce small pilot batches first. These batches are used to confirm curl stability, lash alignment, and overall appearance. Only after this internal validation does full production begin.

Factories that specialize in OEM and private label understand that brand clients care about repeatability. The goal is not just to make one good batch, but to make the same product month after month with minimal variation. This is why production records, mold settings, and process documentation are kept carefully for each private label client.

Packaging: Translating Brand Identity into Manufacturable Design

For private label eyelash products, packaging is not an afterthought. It is part of the product itself. Once lash production is underway, factories work with buyers on packaging structure, materials, and printing.

From a manufacturing perspective, packaging must balance branding with practicality. A box that looks premium but is difficult to assemble or fragile during shipping will create long-term problems. Factories often advise clients on box types that align with their sales channels, whether that is e-commerce, wholesale distribution, or salon supply.

Private label packaging also requires careful coordination between printing schedules and lash production timelines. Delays on either side can affect delivery dates, which is why experienced factories plan packaging production in parallel rather than as a final step.

Quality Control Before Shipment

Before any private label order leaves the factory, quality control checks are performed at multiple stages. These checks usually include visual inspection, curl retention testing, and packaging accuracy. For OEM clients, factories often retain reference samples from approved orders to compare against future production.

This stage is especially important for SEO-driven B2B buyers who search terms like “eyelash factory quality control” or “OEM lash manufacturing process.” In reality, quality control is not a single step, but a series of decisions made throughout production. Factories that treat QC as an ongoing process tend to build stronger long-term relationships with private label clients.

Logistics and Long-Term Collaboration

Once products are packed and approved, factories coordinate shipping based on the buyer’s requirements. More importantly, this is also where long-term collaboration begins. Successful private label projects rarely stop at one order. Brands adjust styles, add new SKUs, or refine packaging based on market feedback.

Factories that understand private label dynamics keep production data and samples on file, making future adjustments faster and more accurate. Over time, this reduces development costs and shortens lead times for new launches.

Communication and Documentation: An Often Overlooked Part of Private Label Production

One aspect of private label eyelash manufacturing that many buyers underestimate is documentation and communication. A professional eyelash factory does not rely solely on verbal confirmation or sample approval. Instead, it creates internal production records that document every confirmed specification, from lash curl and thickness to tray layout and packaging structure.

Final Thoughts

Private label eyelash manufacturing is not just about producing lashes with a logo on the box. It is a structured process that combines material expertise, skilled production, packaging coordination, and quality control. Brands that understand how factories work are better equipped to build stable supply chains and scalable product lines.

For B2B buyers focused on long-term growth, choosing the right eyelash factory is less about finding the cheapest option and more about finding a partner who understands both manufacturing realities and market expectations.