If you’re in the B2B eyelash space, you’ve probably had your share of supplier disasters. Maybe you got a batch of lashes that were all wonky, or a vendor missed your holiday deadline and left you high and dry. Or worse—they ghosted you when clients started sending back faulty products. Getting someone to ship you lashes is easy. Finding a partner who sticks with you when your order doubles, trends change, or things go sideways? That’s the secret to not pulling your hair out—and building a business that lasts.

Most buyers start by hunting for the lowest price. But after a few costly messes, they figure out: cheap upfront often means expensive later. A “budget” supplier can cost you thousands in returns, lost customers, and a damaged reputation. The best long-term suppliers aren’t just people who send you boxes—they’re part of your team. This article breaks down 5 no-nonsense checks to run before you lock in a long-term deal. No fluff, just real-world stuff that separates the good ones from the nightmares.

1. Make Them Fix a Fake Problem (Test Their Attitude)

Every supplier says they “handle issues fast.” But talk is cheap—you need to see how they act when things go wrong before you sign on the dotted line. When vetting a new factory, throw them a curveball. Say something like, “Hey, can we tweak the lash thickness on the sample we talked about?” or “What if we need to switch packaging materials after you quoted us?” How they react tells you everything.

A good partner won’t huff, puff, or charge you a fortune for a small change. They’ll ask questions to get it right: “Do you need the thickness adjusted for salons or online buyers?” and offer a solution: “We can tweak that without pushing the sample back more than 3 days.” We’ve had buyers ask for last-minute tray layout changes because their salon clients complained the old one was hard to use. Instead of saying “no,” we worked with our production team to make it happen. Long-term partnerships aren’t about being rigid—they’re about being helpful.

Steer clear of suppliers who brush you off or say “we never have issues.” Every factory hits snags. What matters is if they fix them without giving you a hard time. If they can’t handle a tiny sample tweak, imagine how they’ll act when you need to scale up or fix a real problem.

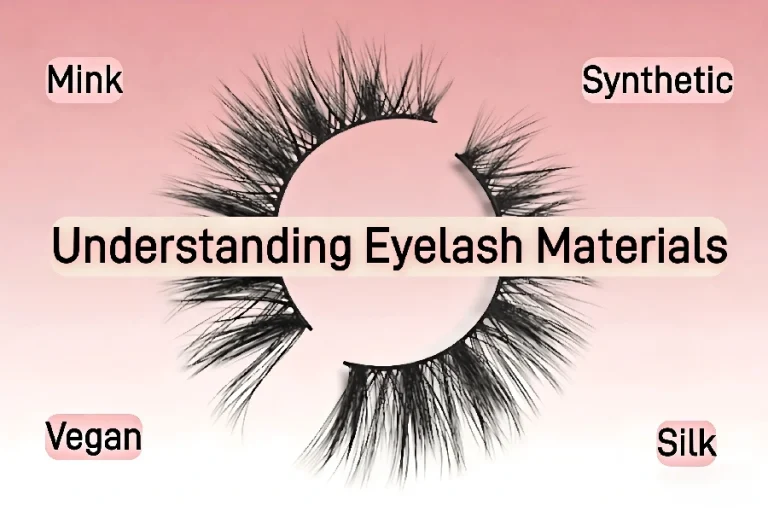

2. Make Them Prove Their Materials (Don’t Buy “Premium” Hype)

Every supplier claims they use “top-quality PBT fiber.” But ask them to show you where it comes from, and most will clam up. For B2B buyers, material consistency is make-or-break. A batch made with cheap fiber will be stiff, lose curl after a few wears, and have your clients screaming for refunds.

When you’re checking out a supplier, demand proof. Ask for material certificates or batch test reports. A trustworthy factory will tell you exactly where they get their PBT—reputable suppliers in South Korea or Japan are a good sign—and how they test it. At our shop, we keep records of every material shipment. We pull 3 random samples from each batch and test them for softness and curl retention. If even one fails, the whole lot gets tossed. No exceptions.

Don’t fall for vague lines like “premium quality” or “top-grade materials.” Make them show you the receipts. If a supplier hesitates to share where their materials come from or how they’re tested, run. They’re cutting corners to offer a lower price—and those corners will bite you later.

3. Test If They Can Keep Up (Don’t Assume They Can Scale)

A supplier who nails a 500-tray order might crash and burn when you need 5,000. So many B2B buyers get burned by “small-batch experts” who can’t keep up when their business grows. One minute you’re celebrating a big order, the next you’re scrambling to find a backup supplier because your current one can’t deliver.

To avoid that, put them to the test. Ask for a quote on an order 3x bigger than what you’re buying now. And make them give you a detailed timeline—not just a vague “we can do it.” A reliable partner will be honest about lead times: “That size order would take 4 weeks, not 2, because we need to reserve production lines.” They’ll explain how they’ll handle the surge—like stocking extra materials or scheduling dedicated time for your order.

We had a client who started with 1,000 trays and blew up to 10,000 in 6 months. Because we planned ahead—we saved their preferred fiber and blocked off production time—we never missed a delivery. Short-term vendors only care about your current order. Long-term partners care about your next one (and the one after that).

4. Check How Fast They Actually Communicate (No More Radio Silence)

Miscommunication is the #1 killer of supplier relationships. Imagine waiting 3 days for a response to an urgent question about your order. Or getting a vague update like “it’s in production” when you need to tell your clients when their lashes will arrive. Clear, fast communication isn’t a nice-to-have—it’s non-negotiable.

Pay attention to how they communicate during the sample phase. Do they email you back within 24 hours? Do they confirm details in writing (not just over a call)? Do they tell you upfront if a sample will be late? A good partner will set expectations early: “We’ll send the sample by Friday. If there’s a delay, we’ll text you by Wednesday.” And they’ll stick to it.

Avoid suppliers who are impossible to reach or use fancy jargon to dodge questions. Over time, you’ll need to talk about everything from packaging tweaks to shipping delays. If you can’t trust them to get back to you now, you’ll be pulling your hair out later.

5. Talk to Their Real Clients (Not Just Read Canned Testimonials)

Testimonials on a supplier’s website are useless—they’re all the good stuff. The real proof of a great partner is other B2B buyers who’ve worked with them for years. When vetting a supplier, ask for 2-3 client references. Preferably ones in your niche—like salon supply or online retail.

Reach out to those references and ask the hard questions: How often do they have quality issues? Do deliveries show up on time? What happens when something goes wrong? We’ve had clients tell references that working with us feels “like having an in-house production team.” Why? Because we flag problems early—like warning them about a fiber shortage 2 months in advance so they can adjust their orders.

If a supplier refuses to share references, run for the hills. They either don’t have long-term clients, or the ones they have are unhappy. A reliable partner will be proud to connect you with their satisfied customers.