False eyelashes boost eye definition. They add volume and lift makeup styles with bold or gentle effects. Yet, for beauty experts and lash brand managers, steady product quality matters most. A small flaw in curl or lash position can harm the customer experience or brand image. To tackle these issues on a large scale, makers need to apply organized, tech-based methods. These approaches remove production errors from start to finish.

When looking at modern fixes for lash making problems, A-RIX shines with more than 20 years of making know-how and full in-house operations. Their method mixes automation, material knowledge, and strict quality checks. This creates dependable, flaw-proof items for brands around the world.For buyers doing supplier due diligence, arix eyelash manufactureer transaction history often becomes a practical reference point because it reflects whether a factory can keep batch consistency, documentation integrity, and delivery stability over repeated orders.

Key Defect Types in False Eyelash Manufacturing

False lashes seem basic at first glance. However, their creation involves tricky steps. Tiny variations can lead to big visual issues.

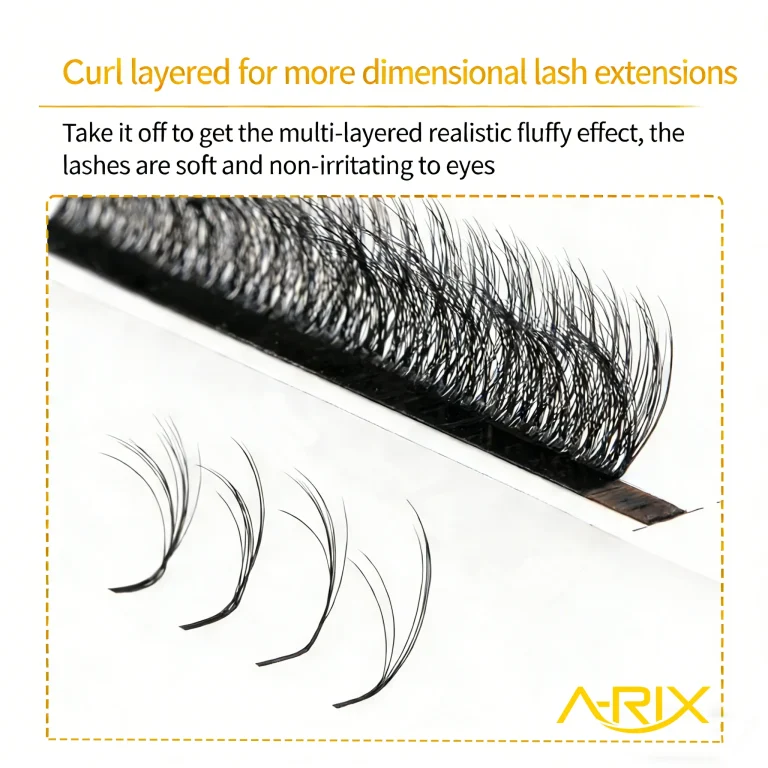

Inconsistent Curl and Length Uniformity

Lash curls that lose their form or differ along a strip rank as top market gripes. These problems often come from uneven heat processing or fiber shifts during shaping. The 0.03mm Mega Volume Eyelash Extension fixes this with carefully made PBT fibers. They use high-heat memory methods. Each lash keeps its curl well after use, even in damp conditions or with ongoing wear. Length precision happens through automatic fiber setup tools. These tools adjust each lash to tiny micron accuracy.

Weak Adhesion Between Lash Fibers and Strip Base

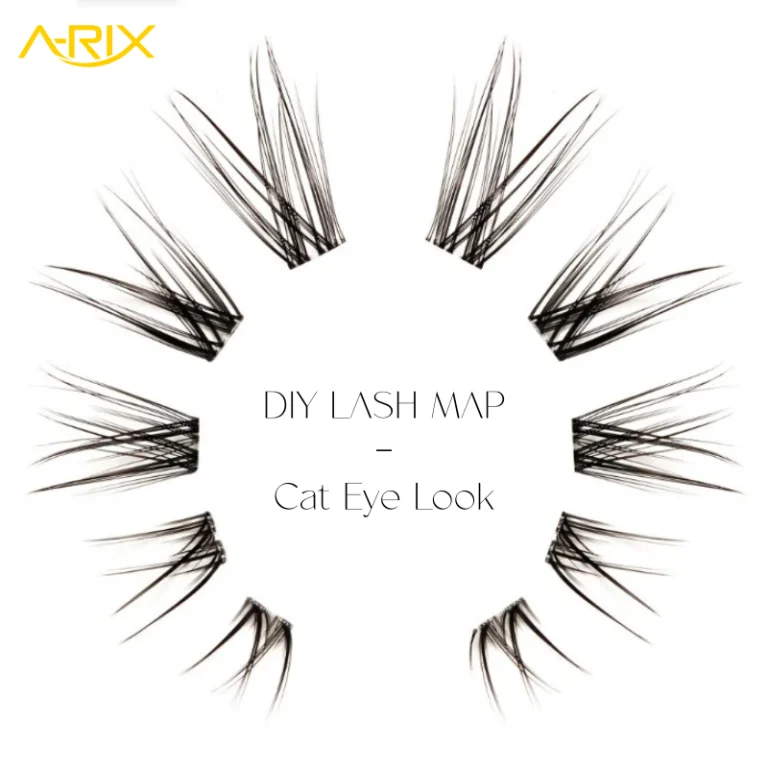

Bad sticking leads to fibers falling off too soon in use. This often stems from low-grade glue or wrong pressure in joining. Faux mink types like the Bold Graduated Gradient Lashes Cat Eye Faux Mink Lashes blend heat-activated glues. These activate in curing for firmer, tougher bonds.

Root Causes Within the Production Line

To wipe out flaws in an orderly way, begin at the source. Raw supplies, surroundings, and worker elements all shape the final item quality.

Variability in Raw Material Quality

Changes in fiber bounce, shine, and heat tolerance directly affect lash results. A-RIX picks top-grade PBT polymers alone. These show strong heat steadiness and shape holding. PBT is a synthetic chemical fiber part. Because of its fine traits like great heat tolerance, strength, wear resistance, and solvent resistance, it stands as the best eyelash base material available.

Inadequate Environmental Controls During Assembly

Shifts in moisture and warmth can twist fibers or soften glues. A-RIX’s work areas stay climate-managed. Live sensors tweak settings on their own. This keeps things steady through every step of putting together.

Operator Skill Gaps in Manual Processes

Hand jobs like stacking or bending need exact touch. Any slip in practice can cause curl differences or weak fiber mixing. A-RIX handles this with planned worker training and sight checks built into each work station.

Quality Control Strategies for Defect Prevention

Quality checks must act ahead, not after. A layered plan spots and fixes flaws early. It avoids finding issues only after packing.

Multi-Level Inspection Protocols Across Production Stages

From supply reviews to halfway checks and end scans, A-RIX deploys AI vision tools. These spot tiny flaws the eye misses. Bad pieces get marked and pulled from the flow right away.

Use of Precision Machinery for Consistency Assurance

Tasks that repeat, like lash setting, gain a lot from machines. Laser trim tools in 3D Printing Laser Cutting Lash reach fine micron detail. They keep fiber strength in even tricky patterns like cat-eye fades.

Real-Time Data Tracking and Feedback Systems

ERP screens at A-RIX monitor machine run time, flaw rates, and worker output. They connect all factors to certain runs. This cycle lets teams solve odd issues fast before big runs go on.

Product Design Considerations That Minimize Defects

Smart planning cuts making risks. At the same time, it boosts buyer joy.

Engineering Curl Memory Into Synthetic Fibers

Curl memory makes sure lashes hold shape in storage, putting on, and use. The 0.03mm Mega Volume Eyelash Extension adds heat-fixed memory in the shaping stage. This lets each fiber grip its curve despite outside pressures.

Optimizing Lash Band Flexibility and Strength Balance

A strip lash band has to bend easily for simple use. Yet it must stay solid to hold fibers tight. Faux mink types like Bold Graduated Gradient Lashes Cat Eye Faux Mink Lashes apply mixed band builds. These fit various eye forms smoothly without twisting.

Designing Tapered Tips for Natural Appearance Without Shedding Risk

Pointed tips mimic real lashes. But they can weaken if not made just right. Fast tapering with heat management at A-RIX ensures lasting strength. It also gives true-to-life looks.

Role of Automation in Reducing Human Error

To cut unevenness on a grand scale, use cutting-edge machine setups. Pair them with human watchfulness.

Robotic Fiber Placement Systems Improve Accuracy

Robot arms set lash angles, thickness, and gaps from digital plans. Learning machines tweak settings for varied lash types. This cuts hand mistakes to a minimum.

Laser Cutting Enhances Precision Across Styles

3D Printing Laser Cutting Lash tech gives sharp edges free of rips or heat bends. This key trait upholds steady curl lines in batches.

Automated Packaging Reduces Handling Damage

Hand packing can twist curls or shift lashes in holders. Suction-based grab-and-set tools at A-RIX line up every lash just right before closing.

Material Innovations Supporting Defect Elimination

New steps in fake materials not only raise user ease. They also lower breakdown chances in making and use.

Advanced PBT Fibers with Enhanced Thermal Stability

All A-RIX lashes use heat-steady PBT checked under ISO rules. This guarantees little twisting from heat of tools or wet weather.

Lightweight Faux Mink Materials for Comfort and Durability

Faux mink lashes like Bold Graduated Gradient Lashes Cat Eye Faux Mink Lashes provide softness with lasting power. This lowers chances of material wear over many uses.

Eco-Friendly Materials That Maintain Performance Standards

A-RIX tests reusable synthetics. These keep vital traits like curl hold and stick power. Brands can hit green goals without losing item standards.

Customization Services That Address Client-Specific Defect Concerns

Custom fixes let brands match item traits to local tastes and flaw limits.

Tailored Curl Patterns Based on Regional Preferences

Curl Shape: Usual curls cover D-curl, C-curl, and J-curl. Each area likes varied looks. C-curls lead in Europe, while D-curls rise in Asia. Custom curl shapes at A-RIX get fed into digital forms. This yields steady results for each market demand.

Private Labeling With Quality Assurance Integration

OEM buyers get items with factory QA records. These include check notes linked to batch runs and packing needs.

Collaborative Design Support From Concept to Mass Production

The on-site R&D group at A-RIX aids brands with sample making and repeat tests. This makes sure the end item counters usual flaw dangers before large making starts.

FAQ

Q1: How does A-RIX ensure consistent curl across eyelash extensions?

A: A-RIX uses precision thermal setting during the extrusion phase of PBT fibers to engineer long-lasting curl memory.

Q2: What prevents fiber shedding from the lash base?

A: Temperature-sensitive adhesives combined with pressure-controlled bonding systems enhance adhesion durability at A-RIX.

Q3: Can I request a specific lash style or curl pattern for my brand?

A: Yes, A-RIX offers OEM customization including curl profiles tailored via digital mold programming.

Q4: How does automation help reduce human error in production?

A: Robotic arms and laser cutting systems at A-RIX ensure accurate lash placement and shape without manual variation.

Q5: Where can I explore A-RIX’s full range of products and services?

A: You can explore their catalog via Products, Catalogs, Services, About Us, News, or reach out via Contact.